Setting up Advanced Energy Thyro A Series PCM Controllers (Local and Remote)

Thyro A Series Installation Guide for Local & Remote Operation

The schematic connections for the Thyro 2A series is outlined below.

Required Connections for General Analogue and Advanced Operation Features

Analogue Control Wiring

1a)Synch In and Synch Out (Pin 6 and Pin 7 on X2) -> For controllers required to operate in synch (including dASM)

The first controller in the chain should have synch out (X2.6) connected to the second controller synch in (X2.7) and so on. The distance between each Controller should be less than 5M for best synch performance.

Note: Do not connect sync directly if using basicbus module as it will connect sync feature through the digital bus

1b) Pulse Lock (Pin 1 and Pin 2 on X2) -> Shorting pins will Enable the controller. Open this link for locked controller/disable/inhibit. RED Pulse Lock LED will blink when the controller is disabled.

Note: The jumper can be replaced with an external interlock circuit capable of switching 24VDC 20mA

1c) Analogue Control Input (Pin 3(-) and Pin 4(+) on X2) and pin 8 for POT input 5V Source -> Connect Positive to X2.4, and negative to X2.3 for Linear Voltage or current input.

1d) Analogue Output (Pin 9 (+) and Pin 10(-) on X2) -> Connect Analogue output to suitable instrument or monitoring device.

1e) Fault Relay (Pins 1(COM),2(NO),3(NC) on X3) -> Connect alarm indication system to Thyro Internal CO Relay K1

Digital Control Wiring

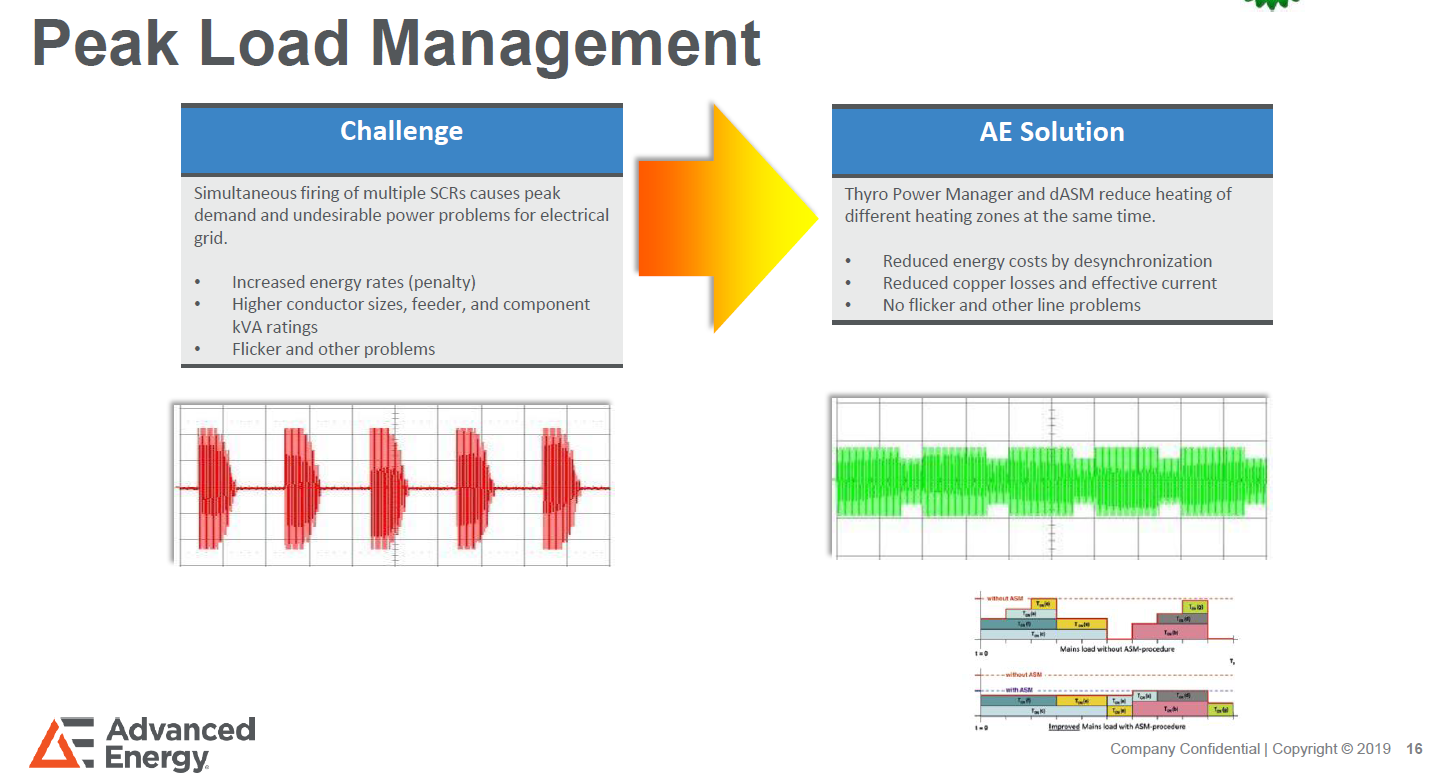

DASM TAKT (Burst Control)

2a) Thyro Bus Wiring (Pins 1 to Pins 7 on X22) to BasicBus Module (Pins 1,2,3,4,6,7,8 on Xxx) -> Connect each Thyro Controller to Basic Bus module , 8 controllers per Basicbus module.

2b) Ethernet Connection to Anybus Module -> Insert Anybus Module to connect to Ethernet IP/Profibus DPV etc etc network.

NON-DASM VAR Sync (Phase Control)

Note the Basicbus module without dASM will use the in built Ethernet connection and does NOT require Anybus Module, or Basicbus Module with dASM Port/Feature.

Power Wiring

3a) Connect incoming mains to screw terminal 1 for module 1 and 2 -> in rotating field supply with White/centre phase connected directly to the load, I.e. Red phase Input (1), Red phase Output (2), White phase connected to the load, Blue phase Input (1), Blue phase Output (2)

3b) Mains Supply input to Thyro Controller (Pin 1 on X1) -> Connect L2 to 2 Amp Slow Blow Fuse, and the other side of the fuse to X1.2

3c) Aux Supply Input (Pins 1 and Pins 2 on X11) -> Not this is NOT required for Controllers where -15%/+10% of rated mains voltage is within these limits.

3d) Aux Supply to BasicBus Module (24VDC 200mA to X11 pins 1(+), 2(-), 3(GND))

Additional Notes from AE

- Using the Thyro-Tool Software is required to select the optional “Ethernet-IP” Plugin module and it makes it a lot easier for diagnostics and to check the communication.

- The “Sync” phase connection is always required for each Thyro-A. The dASM will only work if all Sync (Reference) signals are in phase.

- The Ethernet-IP programming is very simple if a Rockwell PLC is used as we have an AOP with them (Software block).

Other PLCs require a little more definition of the IO-ranges, names and Status-bits if they are required.

- The dASM works automatically and does not require special settings by the software.

Q and A

Q1) What is the IP rating of the controllers? We were planning on mounting them on a wall in an accessible room with the VSD’s.

These would be IP21 finger safe.

We have three heat bank groups. Two 71kW grouped together (group 1), three 5kW grouped together (gruop2) and one 6kW on its own.

Q2) If we wire the sync in and out (X2.7 & 7) between the controller groups as below do we still need to wire X2.6&7 to the Basic Bus Module as per figure 6

- Group 1 - X2.6 on 1st controller to X2.7 on 2nd controller .

- Group 2 - X2.6 on 1st controller to X2.7 on 2nd controller, X2.6 on 2nd controller to X2.7 on 3rd controller.

Question to AE) with Basicbus module do we still need to connect the controller synch directly for mains load optimisation? Or will this be available through the basicbus communications?

The “Sync” phase connection is always required for each Thyro-A. The dASM will only work if all Sync (Reference) signals are in phase.

Essentially what this means is that controllers running in sync needs to Connect through the busmodule and the distance should be no greater than 5M as per AE recommendation

Q3) Do we need to control the controllers via the analogue control input if we are connected via the Ethernet thru the Anybus and basic bus module? Can’t we control the controllers thru the Ethernet?

Correct. You do not need the analogue input is you are controlling via ethernet.

For further Support please refer to the User Manual for Thyro A Series User Manual and Thyro Tool Pro, Basicbus User Manual.

Thyro A Series Quick Setup Guide

Anybus Setup Guide (Ethernet IP)

Contact Fastron techncial sales department for further information on AE(AEG) Thyro Series pricing and capabilities